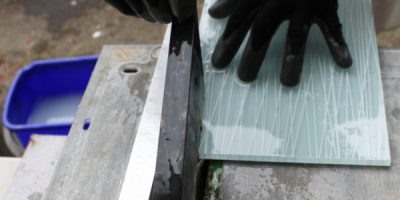

Fused glass tiles are made from intact pieces of glass that are kiln fired at high heat – temperatures ranging from 1100°F to 1500°F.

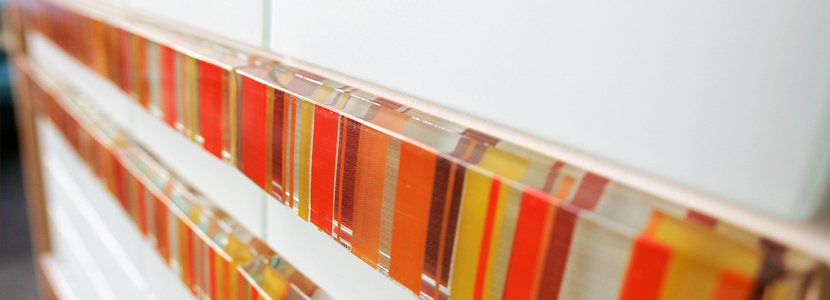

The higher the temperature, the greater the physical change in the glass. Most contemporary fusing methods involve stacking – layering thin sheets of glass. Often different colored pieces are stacked to create visually interesting patterns or simple images.

Fused glass tiles are made from intact pieces of glass that are kiln fired at high heat.

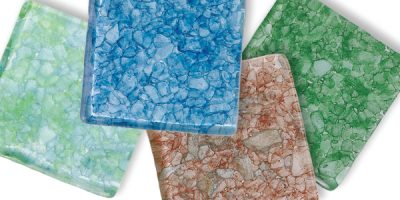

At the lower end of the firing scale, the glass will simply slump – rounding at the edges. The middle temperature range (around 1250°F) creates an effect called ‘tack fusing’, layers of glass that are sandwiched together will marry together, but each piece retains its individual character. Full fusing, at temperatures of 1350 to 1450°F, results in glass sheets flowing together, creating an radically changed look.

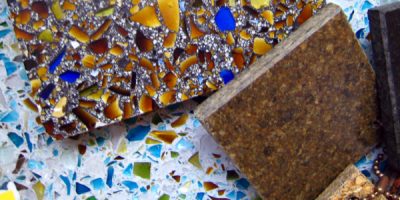

Because these tile are derived from sheets of glass, and not glass powders or shards, there is almost no limit to the sizing. Manufacturers and artisans sometimes used most industrial recycled glass, or spoiled sheets of glass to make this type of tile. However, as different sheets of glass have different pigments and chemical composition, it is impossible to standardize color using; recycled fused glass tile is usually reserved for artisan tiles or ‘rustic’ sheets.

A popular method of fusing involves marries glass to a colored (usually white) background. The color on the back helps reflect light back through the tile, which can give reflected light and the illusion of added space to a room.

Fusing involves a series of ‘ramps’ – rapid heating cycles, and ‘soaks’ – where the temperature is held at a constant level. The longer the kiln is held at the maximum temperature the more thoroughly will the stack fuse. Sustained high heats can devitrify glass, so once the desired fuse is attained, the kiln temperature is lowered. Glass is then annealed – cooled and soaked over specific intervals and temperature ranges. High heat leaves the surface glossy, but this is sometimes modified using etched techniques.